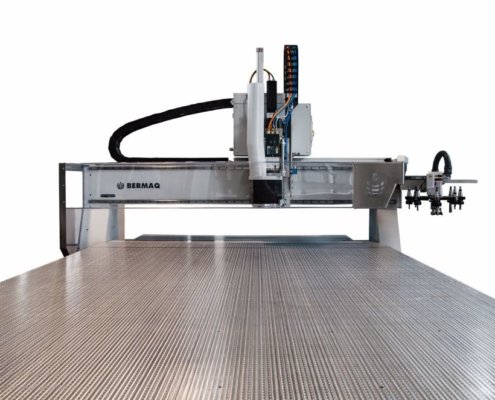

The CNC milling machine VISCOM is ideal for cutting, engraving, milling and rectifying different materials such as plastics and derivatives, acrylic, wood, foam, resins, non-ferrous materials, etc.

This CNC milling machine with high performance stands out for its great robustness, versatility and high-quality finishes. Capable of adapting to all kinds of projects and production rhythms, the BERMAQ® numerical control machine VISCOM guarantees great resistance to the high mechanization demands.

For this reason, it has become one of our customers’ favourite models.

Video

Technical specifications

- Machine equipped with 3 controlled axes.

- Movable bridge structure

- Movable control panel.

- Working length: 3,100, 4,100, 5,100, etc. x 2,050 x 250 mm.

- Z-axis travel: 360 mm.

- Milling head: 8kW to 15kW – ISO30 or HSK-F63; liquid or air cooling system.

- Nominal speed: 12,000 rpm.

- Maximum speed: 24,000 rpm.

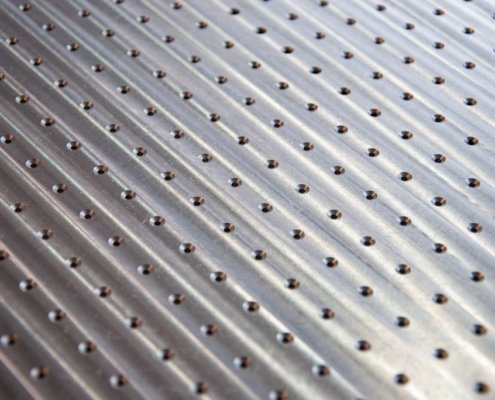

- Working Table: with phenolic resin grid table or micro perforated aluminum table.

- Vacuum clamping system: 290 m³ / h Vacuum pump or 1,000 m³/h variable speed Super turbine.

- Tool length-measuring device.

- Automatic lubrication: ALS system.

- CNC control system to choose from: OSAI, SIEMENS or HEIDENHAIN.

- Tool change: bridge 8 positions revolver, or bench 10 positions linear.

- Movement speed:

- X: 80 m / min

- Y: 80 m / min

- Z: 30 m / min

Applications

- Graphic arts: luminous adverts, advertising panels, stand elements and engraving works

- Industry: electrical appliances, composites, plastics, woods and metals machining

- Construction: Corian, aluminium profiles, PVC and Alucobond for facades

- Decoration: screens, carpets, advertising articles and gifts

Optionals

- Tabletop retractable stops

- Air conditioning

- 2 working areas

- Pneumatic plugs

- Air / liquid tool cooling – VIP4tools

- Cold air tool cooling – Vortex

Descripció

The numerical control milling machine VISCOM has been designed, fundamentally, to work at high speed a wide variety of materials (plastics, woods, aluminium, resins, composites, etc.) and applications. This industrial CNC machine stands out for its robustness, versatility and quality, offering a guarantee of unbeatable productivity.

Its equipment with recirculating ball screws allows high precision in the machining and ensures a high-quality finish. At the same time, its strong structure guarantees greater resistance to continuous work and high machining requirements.

Its compact design makes it a robust and modular CNC milling machine. Its structure allows easy customization of the machine with optimal solutions according to the production requirements of each client. This model has a wide range of custom-made solutions to suit the needs of each project.

The VISCOM CNC milling machine model has become one of the most popular thanks to its easy operation, reliability, speed and, above all, the quality and precision of the finishes.

It is an ideal machine for the sector of signage, machining and scenography, among others.

Sectors