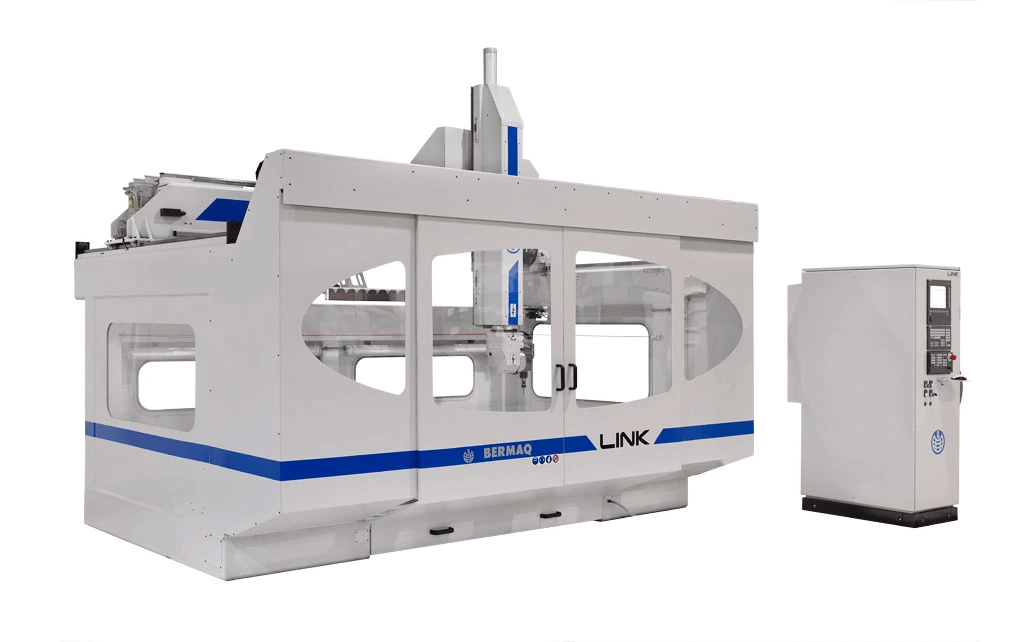

CNC milling machinesLINK

Description

Compact and agile, perfect for machining technical materials.

The LINK model is a 5-axis enclosed machining center. Its compact structure, high power, and versatility facilitate high-speed milling of all types of non-ferrous materials (technical plastics, thermoformed plastics, and their derivatives).

Thanks to its robust mobile gantry structure, it ensures high working speed as well as great precision and quality in finishes. The enclosed structure provides complete isolation of moving parts, offering high safety and additional environmental protection (noise, fumes, etc.).

The table structure allows for easy loading and unloading of workpieces.

FEATURES

Machine with 1 working area

Useful working area with the following options:

Useful length of 2,000, 4,000, 6,000 mm (X-axis)

Maximum useful width 1,650 mm (Y-axis)

Useful height 800 mm (Z-axis)

C-axis = +/- 200º (Harmonic Drive)

A-axis = +/- 110º (Harmonic Drive)

Axis speed:

C-axis: 9,000º/min

A-axis: 9,000º/min

X-axis max. idle speed: 60 m/min

Y-axis max. idle speed: 60 m/min

Z-axis max. idle speed: 40 m/min

8 kW (10.86 HP) liquid-cooled motor

Nominal speed: 10,000 rpm

Maximum speed: 36,000 rpm

HSK / E40 tool holders

CNC Siemens 840 D

APPLICATIONS

Machining of molds and models in aluminum and composite materials.

Machining of resins.

Trimming of structural components in composites.

Machining of carbon fiber, light alloys.

Technical plastics.

The LINK machine from BERMAQ is primarily designed for machining large-format parts, specifically aimed at sectors such as the aerospace, automotive, and mold and die manufacturing industries. The LINK stands out for its ability to perform 3D work and its high precision in milling and cutting complex materials.

Comparative table

Ask for budget

The BERMAQ LINK machine is primarily designed for machining large-format parts, specifically aimed at industries such as aerospace, automotive, and mold and die manufacturing. LINK stands out for its ability to perform 3D work and its high precision in milling and cutting complex materials.

Some of the most common applications for the LINK machine include:

Large-Format Machining: It is ideal for large parts, making it an excellent choice for manufacturing components for the aerospace or automotive industries.

High Precision in Complex Machining: LINK allows for high-precision milling operations on materials such as metals, technical plastics, and resins, especially for parts that require fine details and dimensional accuracy.

3D Machining: The machine is suitable for complex 3D work, making it ideal for creating prototypes or molds with complex shapes.

Various Industrial Applications: Its versatility makes it ideal for a variety of industries that require precision in machining high-strength materials, such as the molding industry, set design, automotive parts manufacturing, and more.

This machine features an advanced CNC control system, which easily handles high-speed machining processes and manages up to multiple axes for complex milling operations. Additionally, its robustness and stability maintain precision over time, reducing downtime and improving production efficiency.

Get news, updates and promotions straight to your inbox.

WORLDMAQ-3 S.L.

Crta. Moli del Castell S/N

Avià 08610 (Barcelona) ESPAÑA

Telf: +34 93 823 1060

Customer service

Monday to Thursday: 07:00-17:00 CET

Friday: 07:00-14:00 CET

For urgent technical service, please send e-mail to

bermaq@bermaq.com

«Financiado por la Unión Europea - NextGenerationEU»