Polishing machinesAMT

Description

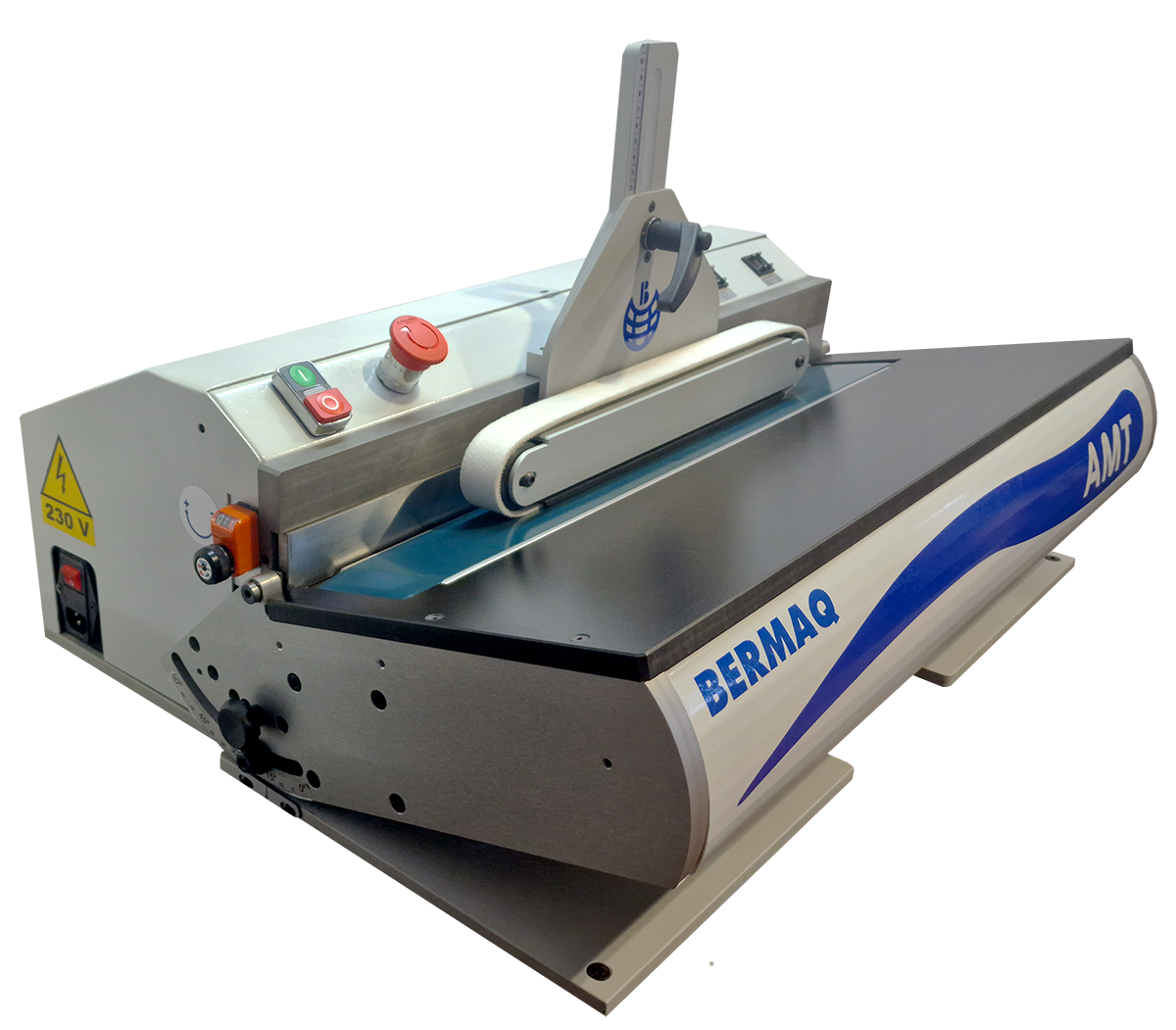

Tabletop acrylic edge polisher with tilting table

The AMT acrylic polishing machine is a tilting-table machine, perfect for machining small parts. Thanks to its adjustable worktable, it can polish edges of straight pieces at 90° or be easily and quickly tilted to achieve angles from -3° to 60° (chamfers and bevels).

The AMT is a very versatile machine, as its compact size allows polishing parts of different materials and thicknesses, both on flat and inclined planes. The result is parts with transparent finishes and optical clarity in a single pass.

This machine is ideal for sectors such as visual communication, signage, displays, POS materials, decorative elements, and the manufacturing of stands and exhibition displays, among others.

Technical characteristics AMT

700 mm

35 mm (straight) / 20 mm (45º)

✔️

✔️

-3º / +60º

Automatic

Up to 3 m/min

7.000 rpm – 12.000 rpm

0 – 1,5 mm

Presser

1

230 V 1PH // 50/60 Hz

792 x 539 x 267 mm

72,5 Kg

✔️

Professional finishes with AMT

The AMT tabletop polisher is an ideal solution for polishing acrylic and methacrylate parts, delivering high-quality finishes in a single pass. The table can tilt within a range of -3° to 60° or be set at fixed positions of 15°, 22.5°, 30°, 45°, or 60°. It is a highly versatile and functional machine, allowing the polishing of straight edges at 90° and beveling—two options in one machine that save space and resources.

The operating system is based on the movement of the piece along the worktable over the conveyor belt. When the piece reaches the midpoint of its path, the diamond tool disc is responsible for grinding and polishing the piece in a single pass. It features a piece presser to hold the part securely on the worktable and a conveyor belt that ensures uniform movement. The cutting depth can be adjusted up to 1.4 mm.

Despite being a compact tabletop machine, its robustness ensures excellent stability during operation and eliminates potential vibrations, contributing to the quality and precision of the finished work.

In summary, the AMT polisher is a practical, easy-to-use, and versatile option for small workshops seeking high-quality finishes on methacrylate parts.

Original BERMAQ® tools

The AMT, like all our polishing machines, works with original BERMAQ® diamond tools, which enables it to achieve finishes of unsurpassed quality (high transparency, shine and smoothness). These finishes are the hallmark for which our machines are renowned. These tools guarantee a maximum finishing quality and a minimum maintenance and adjustment cost. The cutting angles of the diamond tool have been carefully studied for long working life and efficient performance.

Each AMT machine includes:

EIMQ-119001-BQ - Tool for transparent finishing (black/red).

Tools according to material or finish

Part of the success of our polishing machines is also due to the diversity of BERMAQ® diamond tools (different finishes possible).We have different tools to specifically work different types of materials or to achieve different finishes. Discover them all:

Discover them all:

Unbeatable finishes

The quality of the finishes is ensured by the use of original BERMAQ® diamond tools, which guarantee minimal maintenance and adjustment costs. The cutting angles of these tools have been carefully studied to offer a long service life and efficient performance. This also translates into smoother surface uniformity on parts, with smooth, imperfection-free finishes. This is especially important on soft materials such as methacrylate, where any irregularities or imperfections can be more noticeable.

Another factor contributing to the quality of the finish is the ability of the AMT polishing machine to adjust the depth of cut and working angles. This allows the polishing process to be tailored to the exact specifications of each part, ensuring optimum results in terms of smoothness, gloss and dimensional accuracy.

In short, the combination of high-quality diamond tools, precision in the polishing process and customisable settings make the BERMAQ AMT diamond polishing machine® is the ideal choice for top quality finishes on soft materials such as methacrylate, PVC, Alucobond or aluminium.

Comparative table

Ask for budget

The AMT polishing machine has been designed for grinding methacrylate and acrylic (as well as a wide range of soft materials), achieving a transparent finish and a high quality polish.

The AMT is a robust machine, which eliminates possible vibrations and ensures stability during the polishing process. If you are looking for a practical, handy, easy to use, versatile and, above all, with a high quality finish, the AMT methacrylate polishing machine is the machine for you.

Original diamond tools from the manufacturer (BERMAQ) are used, which guarantee maximum finishing quality and minimum maintenance and adjustment costs. The cutting angles of the diamond tool have been carefully studied to obtain a long working life and efficient performance, eliminating the cost of periodic sharpening and tool changes.

Desktop machine for polishing acrylic and methacrylate (PMMA) parts to a high quality finish.The AMT machine can be positioned on the table to achieve bevels or angles from -3º to 60º inclination. The machine, being tilting, can be tilted to any angle between -3º and 60º. However, there are several fixed positions at which the machine can be comfortably positioned. The established positions are 15º 22,5º 30º 45º and 60º.

It is characterised by its great versatility when polishing a wide variety of materials (methacrylate, acrylic, PC, aluminium, resins, PMMA and other non-ferrous materials) and achieving an unbeatable result in each one of them. The finishes achieved with this machine are easily identifiable thanks to the brightness, smoothness and transparency achieved. Ideal for polishing small parts. Recommended for the visual communication sector, signage, displays and POS, decorative elements and the manufacture of display stands.

Original from the manufacturer

The AMT has been designed and manufactured by BERMAQ's technical specialists. It is built piece by piece by hand and undergoes a meticulous final quality test. Trust only original products. Buy from the manufacturer.

100% EU manufacture

All parts used in the manufacture of the AMT come from the EU and are CE marked. The AMT is also CE certified.

Exclusive on the market

Machine with a combination of capabilities and features that make it unique on the market. It is only original if it has a BERMAQ stamp.

Added value in quality

The transparency, shine and smoothness that is achieved after polishing the edges with diamond tools gives the pieces an extra attraction and quality.

Get news, updates and promotions straight to your inbox.

WORLDMAQ-3 S.L.

Crta. Moli del Castell S/N

Avià 08610 (Barcelona) ESPAÑA

Telf: +34 93 823 1060

Customer service

Monday to Thursday: 07:00-17:00 CET

Friday: 07:00-14:00 CET

For urgent technical service, please send e-mail to

bermaq@bermaq.com

«Financiado por la Unión Europea - NextGenerationEU»