The BERMAQ® SG-3 CNC milling machine is the perfect tool for machining a wide variety of materials, in particular polystyrene, plastics, resins, etc.

This milling machine has been designed to meet the most demanding model production jobs. It meets the needs of sectors such as modeLling, shipbuilding, scenography, etc.

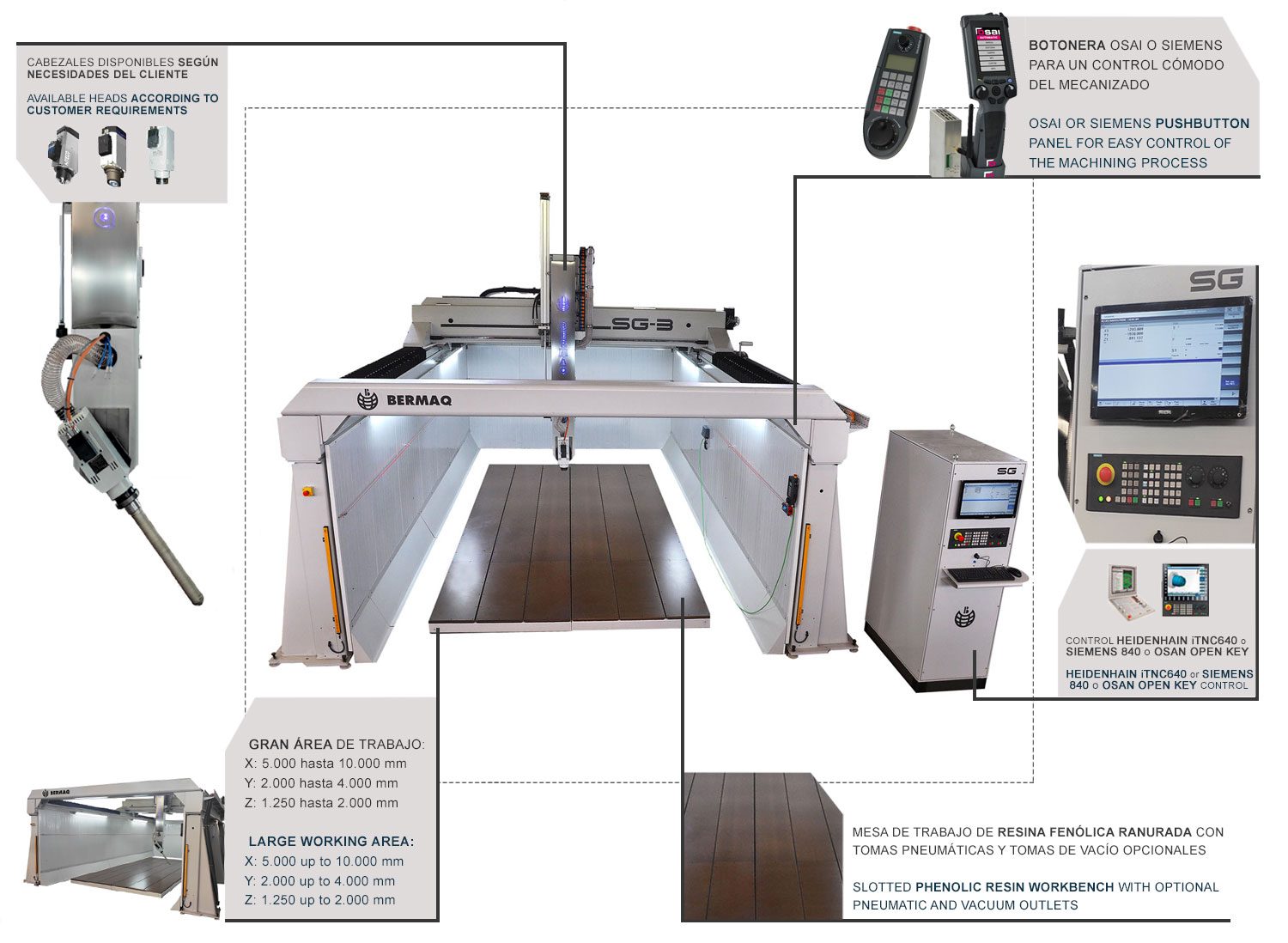

The SG-3 has a modular design that allows customers to choose from multiple combinations and options to ensure that the machine is perfectly adapted to their needs. In fact, one of the main features of the SG-3 numerical control machine is its ability to be customized. The entire BERMAQ® SG range is available with various combinations and options that allow the machine to be tailored to each customer’s requirements.

For 5-axis machining we have the SG-5 CNC milling machine.

It is the perfect milling machine for the production of models and the edging of pieces. It covers the needs of sectors such as the naval, automotive, aerospace, railway, scenography, etc. One of the main features of the SG-5 is its customization capacity.

Video (SG-5 model)

Techincal specifications:

- The machine can be fitted with different milling heads, depending on the materials to be processed. This machine stands out for its efficiency and productivity when making polystyrene molds.

- Head for polystyrene: from 3kW to 8 kW, with internal suction.

- Head for wood and resins: from 8kW to 16kW

- C-axis: Manual (CNC controlled option)

- Automatic lubrication

- Partially cabined machine

- Linear shift from 12 positions (Optional on ISO-30 or HSK-F63 cone motor)

- Air-conditioned electrical cabinet

- Phenolic resin table

- Numerical control of choice:

- HEIDENHAIN iTNC 640

- SIEMENS 840D SL

- OSAI OPEN KEY

- Usable area of the SG-3: Machine prepared to have 3 axes:

- X: 5.000mm up to 10.000mm

- Y: 2.000mm up to 4.000mm

- Z: 1.250mm up to 2.000mm

Applications:

- Model sector: Manufacture of molds in wood, polystyrene, composite, etc.

- Naval sector: hull milling, manufacture of naval furniture and pontoons.

- Aeronautical sector: manufacture of composites of different materials and aluminum parts.

- Railway sector: manufacture of aluminum profiles, cutting of furniture for carriages/wagons.

- Scenographic sector: fallas, large-scale ornamental elements, advertising claims and figures.

Optionals

- Direct encoder to the axes

- Pneumatic brake on the axes

- Double servomotor transmission, master-slave function

- Pressurised precision line rulers

- Suction system

- HEIDENHAIN TS460, RENISHAW touch probes

- RENISHAW NC4 laser tool probe

- MQL lubrication system with air-oil mixture

- Vacuum pump for workpiece clamping

Description

3 or 4 axis machining center specially designed for machining soft materials such as polystyrene, wood, resins, etc. at high speed. It has a high customization capacity, making it a perfect machine to adapt to all types of projects and materials.

Its concept of overhead guidance and modular structure makes it the perfect alternative for the production of models and the machining and edging of medium and large parts. Moreover, thanks to its speed, it is capable of improving production times and making the process profitable. It is a very versatile and efficient CNC milling machine.

It is characterized as a robust, versatile, precise, fast, and flexible machine.

The SG-3 milling machine uses its reach as a working area. This allows it to be very flexible, precise, and able to work with all types of parts, structures, and shapes.

Dimensions of the working area can be customized on request. We adapt the milling heads, power and options, and formats according to the needs of each customer. See the full range of CNC milling machines for more options.

Sectors