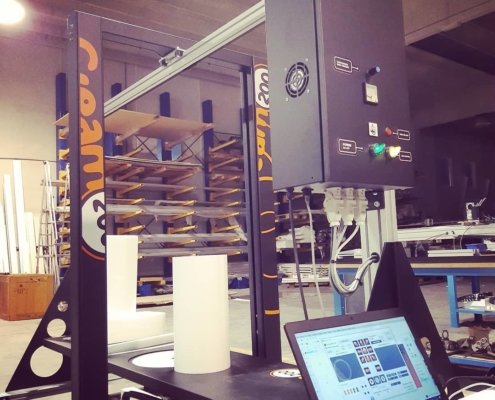

The Cream200 hot wire cutter is the smallest CNC machine for cutting polystyrene manufactured by the Italian brand Nettuno Sistemi (we are official distributors).

Designed and developed to work in the visual communication sector, the Cream200 cutting pantograph, both due to its compact size and low cost, is ideal to be located in graphic companies and architecture and design studios (the best solution for startups or small companies).

The structure of the Cream200 CNC cutting machine is robust and resistant thanks to its powder-coated steel composition. It is equipped with professional components such as recirculating ball bearing guides for high precision of movement. Small, plug & play, easy to use software and very precise, this is the Nettuno Cream200 hot wire cutter.

Video

Specifications

- Área de corte:

- Eje X: 2.000 mm

- Eje Y: 1.210 mm

- Longitud cable: 700 mm

- Diámetro del cable de corte: ø 0,20mm

- Velocidad de los ejes 8.000mm/min

- Tipo de cable de corte: Titanio

- Material de la mesa: Acero

- Estructura: Acero revestido de polvo

- Número de ejes: 3 ejes (2 ejes + torno vertical)

- Tolerancia +/- 0.05mm

- Motor paso a paso

- Fuente de alimentación 220/230 V

- Interfaz del operador Nettuno Cutter

- Software Nettuno incluido

- Incluido el torno vertical

- Teclado inalámbrico de mano incluido

- Mando de control portátil (opcional)

- Pantalla digital (opcional)

- Garantía de 24 meses

Software specifications

- Nettuno CAD / CAM software

- Corel Draw connector

- 5 axis function

- Plot tools

- 3D visualization

- Segment cut mode for radii and ellipsis

- Electronic catalog with columns and cornices

Accessories

- Windows PC, display, keyboard and mouse

- Corel Draw X4 with license included

Applications

- Scenography

- Packaging

- Visual Communication – Graphics

- Showcases – Exhibitions

- Events – Weddings – Parties

Description

The pantograph for EPS and XPS Cream200 is an ideal machine for those starting out in the foam and polystyrene sector, but it is also capable of meeting the production needs of professional and experienced operators. This hot wire cutting machine is suitable for both graphic productions for the visual communication sector and the production of pieces for the building sector.

Nevertheless, it is recommended for the creation of 3d objects, decorations for the theater, parties or events, visual communication, monument signs, cake dolls, gadgets, mall decoration, etc.

The Cream200 hot wire cutting machine table is affordable and also allows companies with a low budget to have a professional CNC cutting machine. It is important to remember that, the economic price of the machine does not affect its quality, which remains the highest.

The quality of its materials, the experience, and the meticulous work of handmade manufacturing combined with the latest technological innovations are the guarantee that Cream200 is a high-performance 2d and 3d CNC foam cutting machine. Equipped with the powerful and intuitive Cad Cam Nettuno software, it allows you to carry out very complex jobs quickly and easily. The Cream200 is a good option for both inexperienced operators and professionals in the sector.

Despite being a 2-axis machine, the vertical turntable (third axis) has been included to be able to cut special 2d and 3d shapes (logos, figures, signs, letters) quickly, accurately, and easily. Thanks to its two axes and one vertical turntable, it also allows us to create shapes even in three dimensions.

Vertical turntable

Thanks to the standard vertical turntable, with the Cream 200 hot wire cutting machine it is possible to make 3D shapes, symmetrical and asymmetrical shapes, spheres, columns, angular cuts, and machining (three-dimensional in general), allowing total freedom to achieve the desired shape.

Wireless keyboard

All Nettuno Sistemi CNC machines are equipped with a wireless keyboard, thanks to which it is possible to perform operations such as jogging movement, play/pause/stop, speed regulation, lathe rotation or check the axis dimensions.

Sectors