BENEFITS OF POLISHING ACRYLIC WITH DIAMOND POLISHING MACHINE

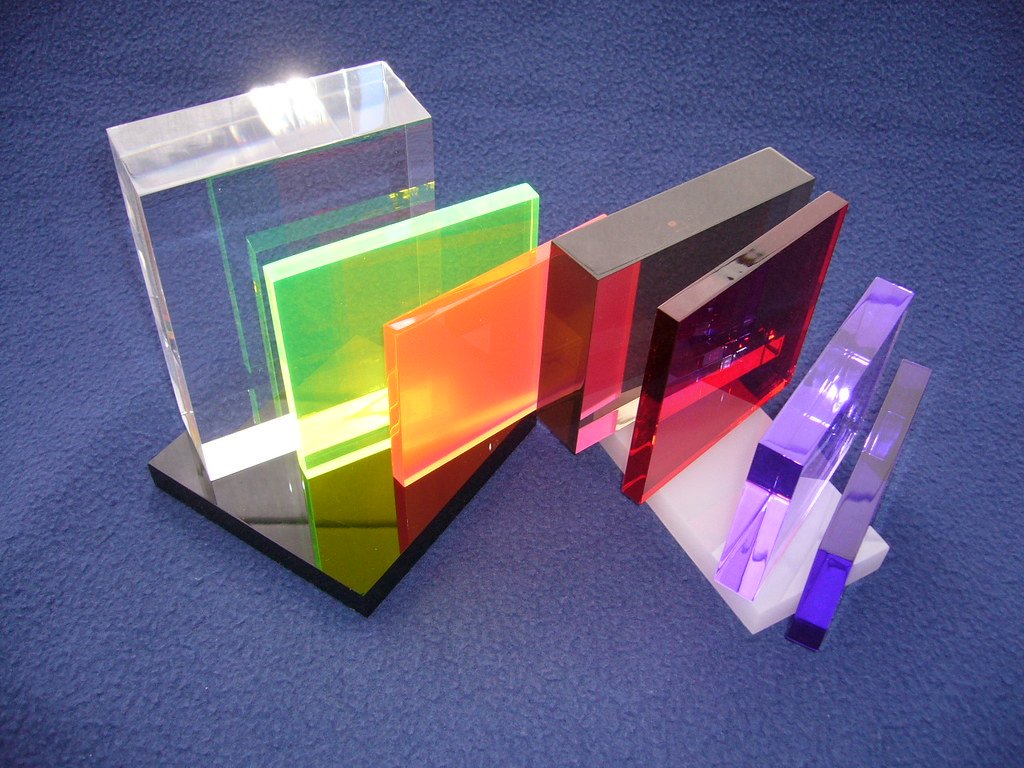

Polishing methacrylate has become an indispensable process to achieve quality pieces. It is essential to highlight its qualities. By polishing the edges of this material and other types of plastics such as polycarbonate, acrylic, PETG, PMMA. PC, PS, or other technical plastics, even aluminum, the workpiece is given much more light, shine, smoothness, and transparency. With shiny edges and free of marks created by the cutting tools, the methacrylate pieces get greater transparency, where an added value to the piece.

ACRYLIC APLICATIONS

Acrylic plexiglas is a material in great demand due to its multiple applications and advantages. In general, it is used in products requiring high durability, high color stability, or weather resistance. Its main advantages over other materials such as polycarbonate (PC) or polystyrene (PS) are weather resistance, transparency, and scratch resistance. For this reason, acrylic is used in the automotive industry, lighting, displays, cosmetics, shows, decoration, jewelry, furniture, events, points of sale, exhibitions, construction, and optics, among many others.

More recently, with the arrival of the pandemic caused by COVID-19, acrylic has been the material used for anti-contagion shields and protective screens. One of the main characteristics of acrylic protection screens is that it has a non-porous surface, which facilitates proper disinfection. In addition, thanks to being a transparent material, it allows seeing through it, protecting people from contact with other people without having to prevent visual contact between them.

POLISHING ACRYLIC EDGES PROVIDES GREATER TRANSPARENCY AND, THEREFORE, HIGHER QUALITY.

WHY POLISHING ACRYLIC PLEXIGLAS EDGES?

Once the cut parts are available, it is necessary to work the machined areas to achieve a good finish of the product, eliminating the marks produced in the cutting and machining. This process is characterized by eliminating the roughness, marking, or scratching caused in the handling by CNC machining cuts or other saws.

In addition to the aesthetic factor, polishing the edges of the plastic eliminates the imperfections that often cause cracks. Thus, we are not only giving it more shine and transparency but also more resistance.

HOW TO POLISH ACRYLIC EDGES

The polishing process can be carried out in several ways depending on the finish to be presented.

One of the options to polish the edges is to use a mechanical polishing machine working at around 1500 rpm and separating the machine from the methacrylate when necessary to prevent it from deforming due to the temperature generated by friction. The experience is necessary in this type of operations since to obtain an optimal polishing it is necessary to combine rotation speed and pressure on the material.

Also, from an industrial perspective, the edges can be polished by means of a high-temperature air jet or flame. These two options are advisable when polishing acrylic pieces with circular or rounded shapes or with drilled spaces in them. Both polishing options require the intervention of an operator at all times since he will be the one who must manually apply heat or air to the piece. This polishing process requires both an economic investment to acquire the air or flame polishing machine and, in addition, the investment in labor.

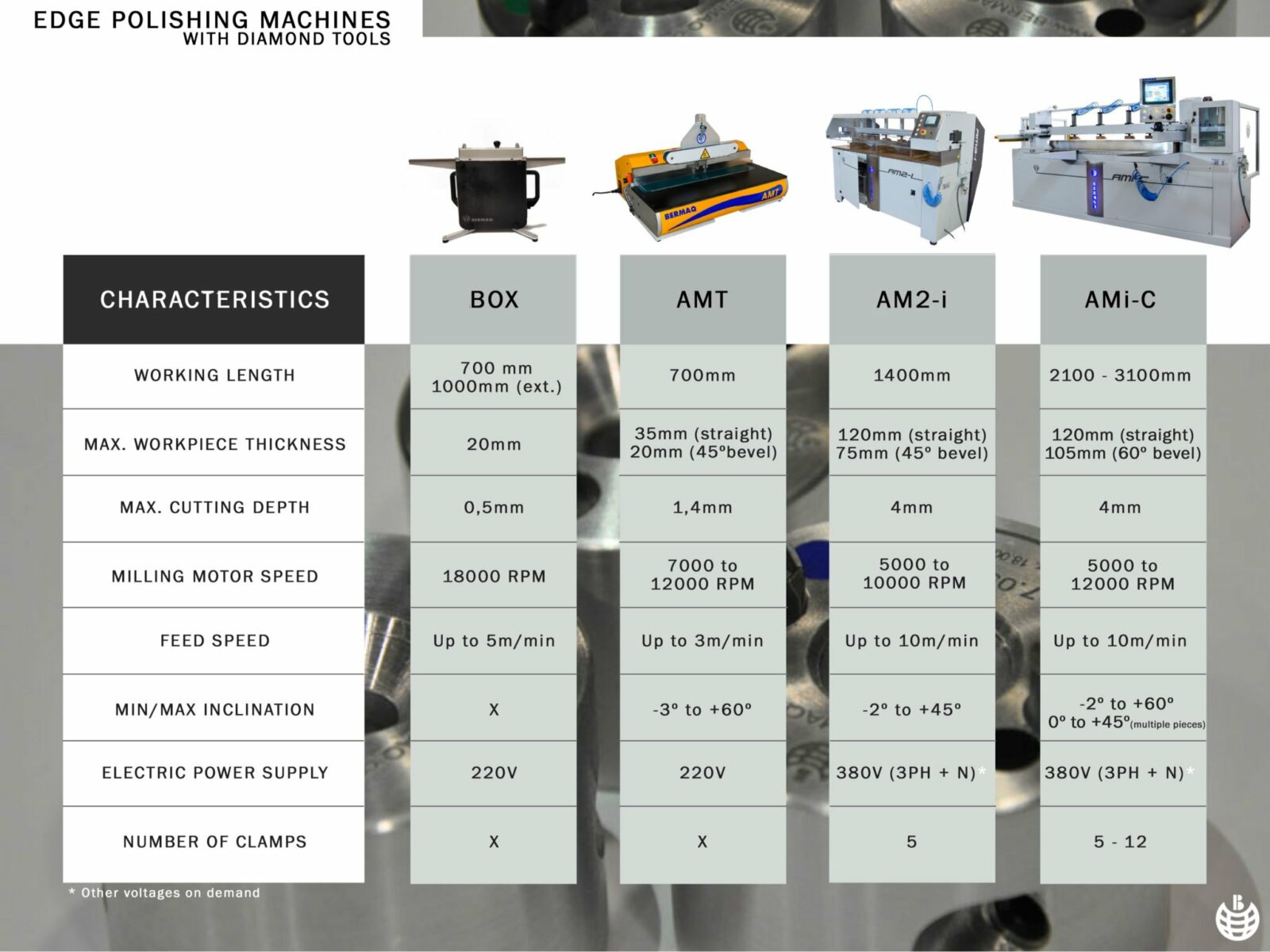

Finally, and as a recommended option, there are automatic polishers with diamond tools that achieve high-quality results with a single pass: these tools can polish both straight edges and angled edges (beveling). These polishers offer the possibility to polish the edges of any non-ferrous compact material, such as polycarbonate, acrylic, PETG, PMMA, PC, PS or other technical plastics. PC, PS or other technical plastics, including aluminum.

The result is articles with the advantages of polishing and buffing, polished edges that provide high optical quality at joints and more transparency, clarity and gloss in the overall product. This results in a piece that is more elegant and sophisticated to the eye.

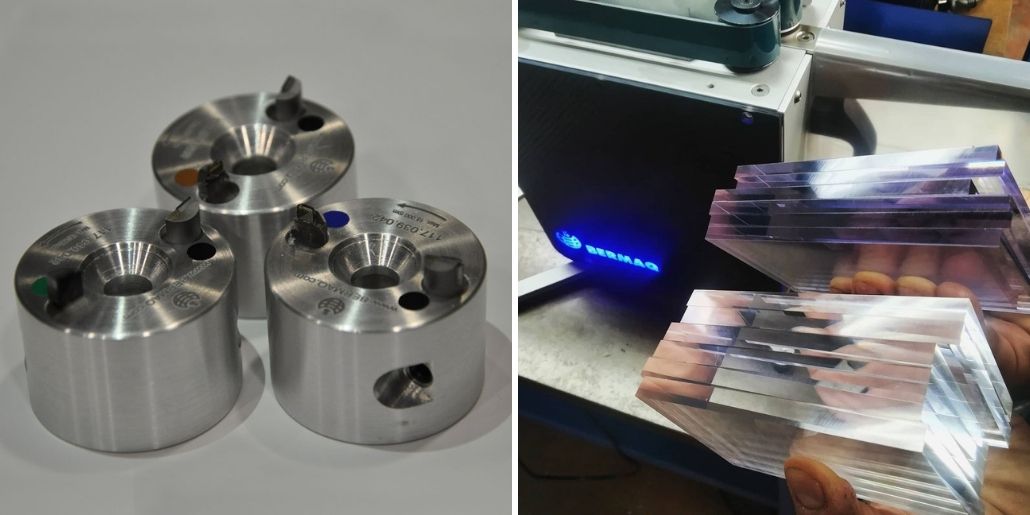

DIAMOND TOOLS FOR ACRYLIC POLISHING

Diamond cutting tools are used for grinding and polishing of methacrylate and other plastic materials due to their high hardness and strength.

These not only allow the processing of methacrylate, PMMA (colored PMMA, extruded, mineral…), polycarbonate, PET-G, SAN and many other plastics, but also light metals such as aluminum or mixed materials (methacrylate + aluminum, methacrylate + paper, etc.).

The long service life of these tools should be emphasized as well as their minimal generation of dust/chips.

THE MOST EFFICIENT SOLUTION TO OBTAIN TRANSPARENT ACRYLIC PMMA IS A POLISHING MACHINE WITH DIAMOND TOOLS.

For more information contact bermaq@bermaq.com or call +34 93 823 10 60. web: www.bermaq.com